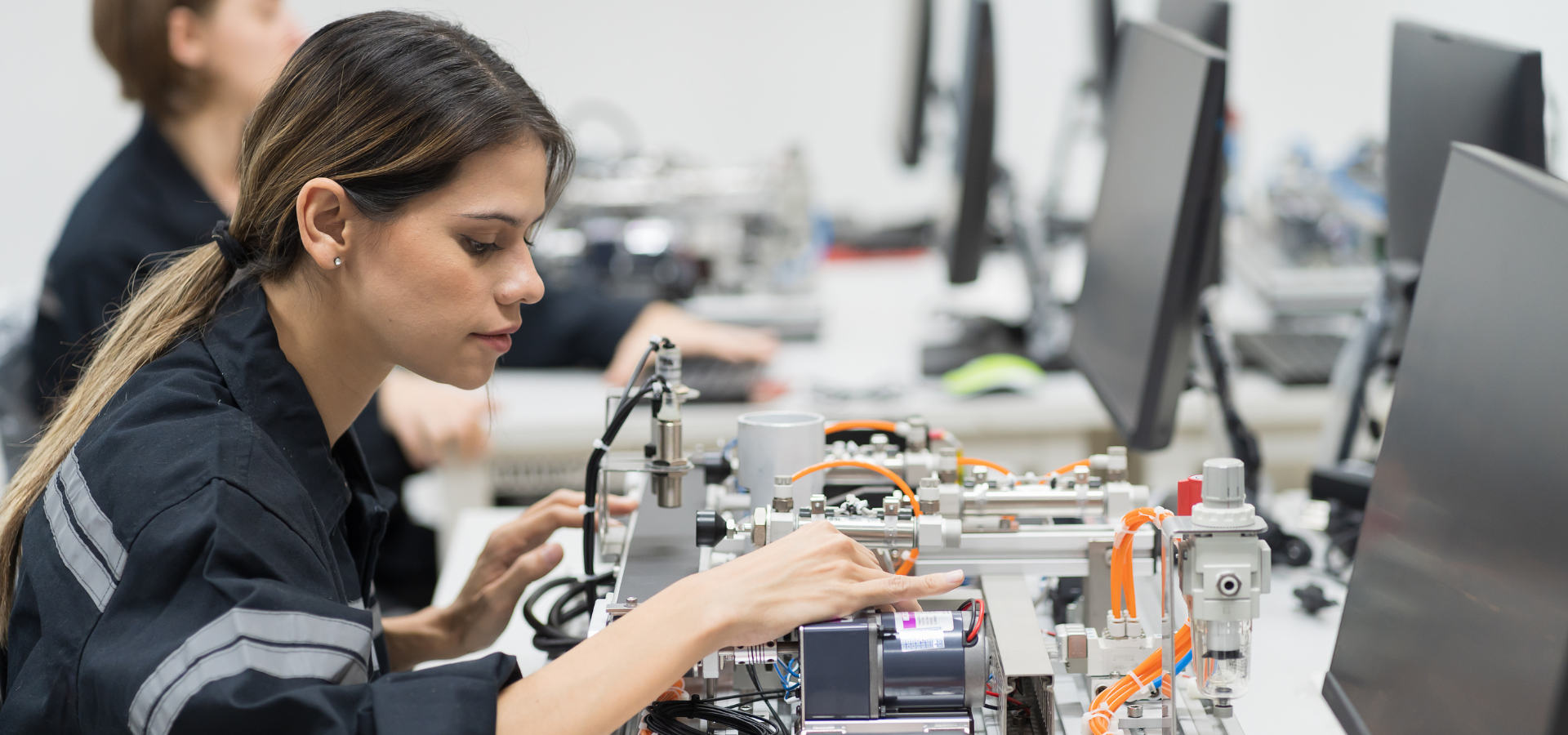

Industrial Maintenance / Mechatronics Technician

Repair, install, adjust, or maintain industrial production and processing machinery or refinery and pipeline distribution systems. May also install, dismantle, or move machinery and heavy equipment according to plans.

|

Jobs available locally 2,985 |

Demand Locally +3 % |

Annual Wage Range $39,575 – $84,896 |

Help installation, maintenance, and repair workers in maintenance, parts replacement, and repair of vehicles, industrial machinery, and electrical and electronic equipment. Perform duties such as furnishing tools, materials, and supplies to other workers; cleaning work area, machines, and tools; and holding materials or tools for other workers.

|

Jobs available locally 1,298 |

Demand Locally +2 % |

Annual Wage Range $24,565 – $50,294 |

Research, design, develop, or test automation, intelligent systems, smart devices, or industrial systems control.

|

Jobs available locally 1,006 |

Demand Locally +2 % |

Annual Wage Range $72,408 – $176,138 |

Program Level:

Certificates, Continuing Education

Department:

Continuing Education

Institute:

Advanced Manufacturing & Logistics

College:

SPC

Industrial Maintenance /

Mechatronics Technician

Are you a maintenance technician seeking to increase your skills and advance your career? Are you interested in gaining the skills necessary to become employed in the high demand field of industrial maintenance? Are you a manufacturing employer seeking to enhance the knowledge and skills of your maintenance workforce? Alamo Colleges Industrial Maintenance / Mechatronics Technician program was designed to meet the diverse needs of employers and individuals! With this training, you will boost your ability to achieve. For more information on class schedule contact 210-486-2740.